Understand the Types of Foam for Packaging matter when shipping across the United States because millions of parcels move every day and many face rough handling. Every year the U.S. sends more than 100 billion packages, and carriers transport packages in sorting facilities, trucks, and airplanes where drops and crashes occur regularly.

Selecting the correct foam reduces return charges, less breakage, and keeps consumers happy. Small sellers and large brands both gain when packing teams pick the right foam, test it, and track damage rates to improve protection and lower waste.

Shipping teams must match foam to product weight, shape, and fragility. A wrong foam choice lets items shift, hit box walls, and break. A good foam choice absorbs impact, holds the item steady, and fits inside the box without wasting space.

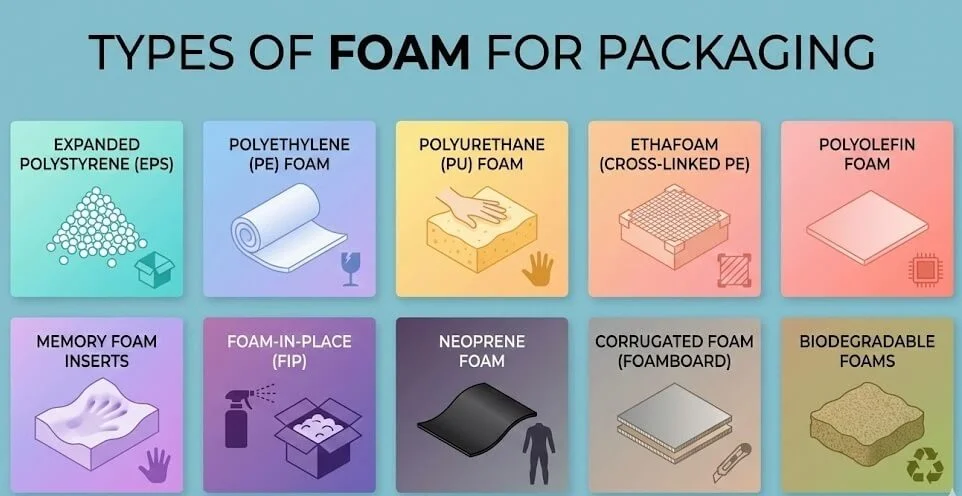

10 Types of Foam for Packaging for Your Product Safety During Transit

This guide explains ten common foam types, how each protects products, and when to use each one. The guide uses plain words and clear tips so packers and product teams can choose fast and test smarter.

1. Expanded Polystyrene (EPS)

Growing strong support and crush resistance allow polystyrene to be especially suitable for heavy, steady goods. Reduced movement and decreased breakage result from molded EPS fitting tight forms and securing pieces firmly under rough handling. The foam costs less than many other options and gives strong compression resistance for stacked shipments. Recycling options vary by city, so check local rules before choosing EPS for large runs.

Use molded EPS for electronics and appliances when rigid support matters and budget limits exist. Types of Foam for Packaging like EPS work best when the item needs rigid support and a low-cost cushion.

- Best for: Electronics; appliances.

- Pros: Low cost; strong compression resistance.

- Cons: Recycling varies by location.

- Tip: Use molded EPS for heavy, stable items.

- Valuable for: common in molded inserts.

2. Polyethylene (PE) Foam

Through several uses, polyethylene foam provides soft yet constant cushioning. Cross-linked PE is perfect for regular shipments and returns because it holds form and resists tears. PE helps medical instruments and tools remain dry and clean during transportation by repelling water and most chemicals.

Though more expensive than EPS, the foam pays off when reuse reduces waste and saves money. Cut PE to fit boxes or utilize die-cut inserts for rapid packing and uniform protection. When the product has to be handled often and has to be protected over time, turn to PE.

- Best for: Tools; medical devices.

- Pros: Water resistant; reusable.

- Cons: Higher cost than EPS.

- Tip: Pick cross-linked PE for repeated use.

- Useful for: great for repeated shipments.

3. Polyurethane (PU) Foam

It helps delicate glass and equipment survive drops since it absorbs vibrations well and adapts to odd shapes. While open-cell PU offers a soft contact layer, closed-cell PU protects sensitive parts and prevents moisture from entering. It absorbs energy on impact and reduces vibrations on long trips, therefore delicate items arrive undamaged more frequently. You can use it for Perfume Gift Packaging.

Test PU with drop trials to find the right density for each item and route. Use PU when the product needs a snug, shaped fit and strong shock control.

- Best for: Fragile glass; instruments.

- Pros: Excellent energy absorption.

- Cons: Can degrade with moisture.

- Tip: Use closed-cell PU in damp places.

- Helpful for: ideal for delicate items.

4. Ethafoam (Cross-linked PE)

Ethafoam is ideal for industrial components and heavy gear as it withstands extreme weights and preserves shape under pressure. To prevent movement and safeguard edges during long hauls, cut Ethafoam to fit crates and pallets. When components reside in storage or travel via challenging supply chains, the foam helps by resisting tears and chemicals.

Ethafoam takes more space than thin foams, so plan box size and cost before ordering large quantities. Use it when the product needs long-term protection and repeated handling in tough conditions.

- Best for: Industrial parts; heavy gear.

- Pros: Durable; chemical resistant.

- Cons: Bulkier than other foams.

- Tip: Cut to fit crates for heavy loads.

- Ideal for: used in industrial shipping.

5. Polyolefin Foam

Polyolefin foam gives a soft touch and steady shock control while staying light in weight. Use it for consumer electronics and cosmetics where surface finish and feel matter during unboxing. It can often recycle better than EPS in certain areas. Thus, it helps businesses meet consumer expectations and meet environmental goals. Order Custom Retail Display Boxes with foams to protect your products.

The price relies on foam density; therefore, select the right thickness for the weight and fragility of the item. Use thin sheets for surface protection and thicker layers for drop resistance to balance cost and safety.

- Best for: Consumer electronics; cosmetics.

- Pros: Lightweight; recyclable in some streams.

- Cons: Cost varies by density.

- Tip: Use thin sheets for surface protection.

- Perfect for: good for retail items.

6. Memory Foam Inserts

Memory foam hugs shapes and cuts vibration, so it protects precision tools and optics during long trips. Custom-cut memory foam gives a tight fit that lowers movement and damage and improves the unboxing feel for premium products. The foam costs more than standard options, but it reduces returns for high-value items and boosts perceived quality.

Add a thin outer layer of firmer foam for extra drop protection when needed. Use memory foam for products that need a soft contact layer and a precise hold. You can use a Jewelry Box With Foam Insert for this purpose.

- Best for: Precision tools; optics.

- Pros: Custom fit; premium feel.

- Cons: Higher price.

- Tip: Use for high-value items to lower returns.

- Appropriate for: adds luxury protection.

7. Foam-in-Place (FIP)

It locks the product in place and builds a custom shell around it, hence supporting unusual shapes and concepts. Because the foam sprays into the box and sets quickly, packers may move swiftly on custom orders and low-volume runs. FIP offers great protection and fits ideally, but many systems utilize it once then dispose of the foam; so, schedule for trash or reuse whenever possible.

Use FIP when testing reveals good results and the item calls for a formed fit. Follow the product instructions during application and always have safety gear available.

- Best for: Irregular shapes; prototypes.

- Pros: Perfect fit; fast setup.

- Cons: Often single-use.

- Tip: Use for one-off or low-volume shipments.

- Suitable for: excellent for odd shapes.

8. Neoprene Foam

Suitable for car parts and hardware exposed to severe conditions, neoprene withstands oil, heat, and many chemicals. Handling harsh conditions and extended storage, the foam helps to maintain shape and safeguards corners from damage. Plan shipping cost and box strength to avoid shocks as neoprene is heavier than PE.

Use neoprene if the product presents heat or chemical risk during storage or transit and if the packing calls both cushioning and resilience to demanding circumstances.

- Best for: Automotive parts; hardware.

- Pros: Chemical and temperature resistant.

- Cons: Heavier than PE.

- Tip: Use where environmental risks exist.

- Excellent for: suited for harsh conditions.

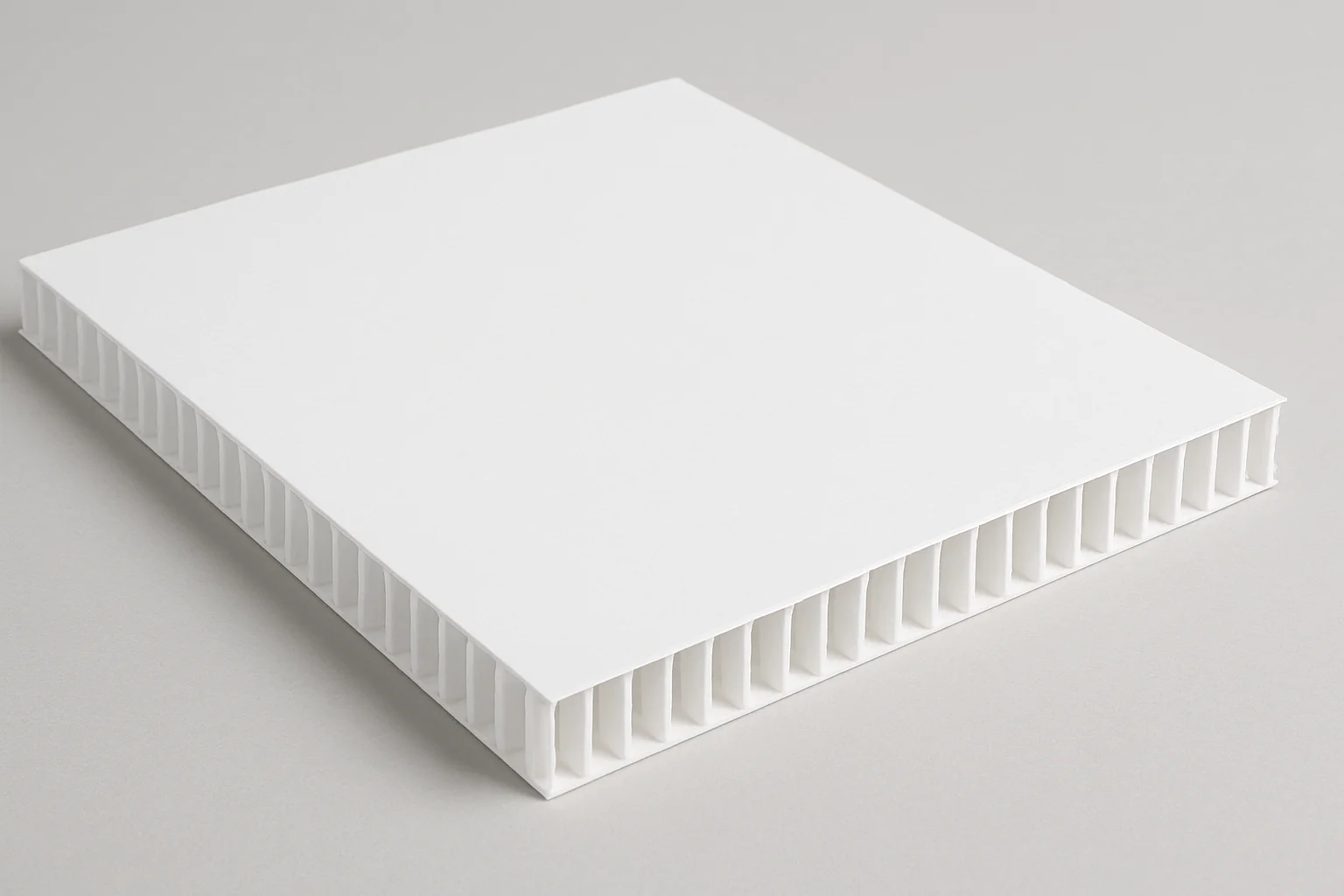

9. Corrugated Foam (Foamboard)

Corrugated foam gives flat support and adds structure for prints, flat electronics, and framed art. The foamboard stays light and cuts easily to size, which helps packing teams work fast and keep costs low. Pair foamboard with bubble wrap or corner protectors for better drop protection on heavy flat items, since foamboard alone does not absorb deep shocks.

Use foamboard when surface protection and a tidy look matter more than deep cushioning, and add layers for full protection on heavier goods.

- Best for: Prints; flat electronics.

- Pros: Lightweight; easy to cut.

- Cons: Less shock absorption for heavy items.

- Tip: Pair with bubble wrap for drops.

- Custom-fit for: good for flat goods.

10. Biodegradable Foams

For eco-conscious companies to reduce long-term trash, biodegradable foams employ plant-based material or unique combinations that degrade more quickly than conventional plastics. These foams work for many light to medium things and minimize the environmental impact when companies select them and evaluate them properly. Use these foams with Custom Bakery Boxes With Window.

Given that the cost and strength differ by formulation, test the foam for every product and delivery path before full use. Before selecting biodegradable foam for significant runs, verify local compost and recycling guidelines to avoid unexpected outcomes.

- Best for: Eco-conscious brands.

- Pros: Lower environmental impact.

- Cons: Cost and availability vary.

- Tip: Check local compost rules before choosing.

- Designed for: Luring eco-conscious customers.

Types of Foam for Packaging

|

Foam Type |

Best for |

Pros |

Cons |

Tip |

Use |

|---|---|---|---|---|---|

|

Expanded Polystyrene (EPS) |

Electronics; appliances |

Low cost; compressive |

Recycling varies |

Molded for heavy items |

Molded inserts |

|

Polyethylene (PE) Foam |

Tools; medical devices |

Water resistant; reusable |

Higher cost |

Cross-linked for reuse |

Die-cut inserts |

|

Polyurethane (PU) Foam |

Fragile glass; instruments |

High shock absorption |

Moisture can degrade |

Use closed-cell if damp |

Snug shaped fits |

|

Ethafoam (Cross-linked PE) |

Industrial parts; heavy gear |

Durable; chemical resistant |

Bulky |

Cut to fit crates |

Pallet/crate padding |

|

Polyolefin Foam |

Consumer electronics; cosmetics |

Lightweight; recyclable |

Cost varies by density |

Thin sheets for surface |

Retail displays |

|

Memory Foam Inserts |

Precision tools; optics |

Custom fit; premium feel |

Expensive |

Add firmer outer layer |

Luxury packaging |

|

Foam-in-Place (FIP) |

Irregular shapes; prototypes |

Perfect fit; fast |

Often single-use |

Use for low-volume runs |

Custom shells |

|

Neoprene Foam |

Automotive parts; hardware |

Heat/chemical resistant |

Heavier |

Use where environment risks exist |

Harsh-condition parts |

|

Corrugated Foam (Foamboard) |

Prints; flat electronics |

Lightweight; easy cut |

Low shock absorption |

Pair with bubble wrap |

Surface protection |

|

Biodegradable Foams |

Eco-conscious brands |

Lower environmental impact |

Cost/availability vary |

Test formulations locally |

Sustainable packaging |

FAQs

How to choose foam density?

- Match foam density to item weight.

- Use higher density for heavy items.

- Use softer layers for fragile surfaces.

- Run drop tests to confirm protection.

- Balance cost and safety for each SKU.

- Track damage rates and adjust density as needed.

Does foam protect from moisture?

While some foams absorb water, others do not; so, closed-cell foams are best for wet settings. Closed-cell PE and neoprene repel moisture and maintain object dryness. For humid routes, avoid open-cell foams as they can entrap water and ruin sensitive products. Add desiccants when humidity causes a genuine threat and seal boxes.

How to test foam performance?

- Run drop tests from common heights used by carriers.

- Use vibration tests to mimic truck travel.

- Check compression under stacked loads.

- Inspect items after transit for damage.

- Track damage and return rates over time.

- Adjust foam type and density based on test results.

How much foam goes in a box?

- Fill voids fully to stop movement.

- Keep 1–2 inches between item and box walls.

- Use layered foam for heavy items.

- Test with drop trials to confirm safety.

- Balance foam volume with shipping cost.

What is foam-in-place?

Foam-in-place sprays a liquid foam that expands and cures around the product to form a tight shell. The method gives a custom fit and strong protection for odd shapes. Use FIP for prototypes, low-volume runs, or items that need a molded fit. Follow safety steps and test cured foam before shipping.

Order Types of Foam for Packaging and Find Your Perfect Fit

Choose the right Types of Foam for Packaging today. Pick one foam type, run simple tests with the product, and cut damage and returns. For help choosing the best Types of Foam for Packaging for specific items, contact Packaging Company and start testing samples now.