Nevada shows real growth in packaging and light manufacturing. The state reached a manufacturing output of about US $6.07 billion in recent years, which made up a little over 4% of Nevada’s full economic output at that time. Local packaging and labeling services counted around 129 employees statewide, providing full support to companies that need Custom Packaging and Custom Boxes Nevada.

Large and small companies in the state order custom printed boxes NV for shipping, retail display, production needs, and seasonal sales. Nevada’s steady growth brings more demand for new box styles, better print options, and more durable box materials.

12 Ways to Buy Custom Boxes Nevada

This guide helps buyers understand the process and gives clear steps for smart decisions. Every tip uses simple language and direct guidance.

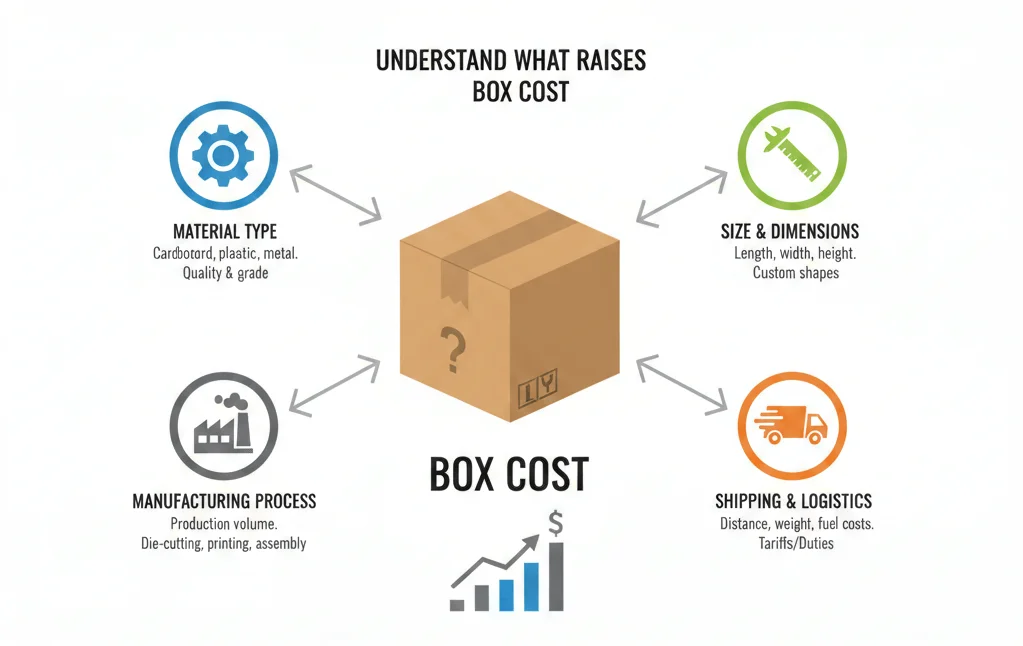

Tip 1: Understand What Raises Box Cost

Smart buying starts with clear information. A few factors raise costs more than others. These factors include size, material, printing, finish, and order volume. Larger Custom Boxes Nevada use more paper and raise cost. Stronger materials raise cost. Special finishes also raise cost. High-volume orders lower cost because production setups spread across more pieces. Clear planning always leads to fewer mistakes and fewer surprises.

Key points that raise or lower price include:

- Box size

- Box shape

- Material strength

- Print style

- Color amount

- Extra coatings

- Order volume

A small box uses less material and print space, so the price stays lower. Heavy rigid boxes use more labor and stronger boards, so the price rises. A simple print with two colors costs much less than a full wrap with foil or embossing. A large order cuts the price per box because one setup handles thousands of units. Good planning creates good savings.

Many Nevada brands choose simple layouts because these layouts lower cost and still look clean. A balanced design keeps brands strong without stretching budgets.

Tip 2: Order Larger Quantities When It Makes Sense

Bulk orders cut costs for most box styles. A larger order spreads setup costs over many units. A long-term plan helps businesses avoid volume problems during busy seasons. Good bulk ordering works best for products with stable demand.

Benefits include:

- Lower price per box

- Fewer delays

- Fast production

- Clear stock planning

Bulk buying also creates steady inventory for online shops and retail stores. Bigger orders need space, though, so businesses should plan storage before they order. A strong plan avoids crowding stockrooms or raising warehouse rent.

Bulk orders help small companies look more professional because stock stays constant. This also leads to fewer rush orders, and rush orders often cost more. Nevada companies with growing online sales benefit the most because steady volume supports steady shipping.

Tip 3: Pick the Right Material for the Job

Every product needs the right box material. The best choice depends on weight, fragility, brand look, and price goals. Nevada businesses choose different materials for different needs. Protective boxes ship fragile items safely. Smooth carton boxes work best for display and cosmetic goods. Kraft boxes offer an earthy, natural look. Thick rigid boxes offer a premium feel for special products.

Common materials include:

- Thin paperboard for small retail goods

- Custom corrugated boxes for mailing and shipping

- Kraft or recycled material for eco-focused items

- Rigid board for luxury goods

A shipping box needs strength and shock resistance. A small retail box needs a clean look and sharp print. A luxury item needs a heavy feel and smooth edges. A natural item sells better with a kraft board because customers trust earthy colors.

Nevada brands often blend two materials, like a kraft outside with a white inside for simple branding. Smart material choices also reduce returns from damaged shipments. Strong material design builds customer trust, and trust builds repeat sales.

Tip 4: Keep the Design Simple for Lower Cost

Simple design makes ordering easier. Simple layouts also lower cost because they use fewer colors and less print coverage. Busy designs raise ink usage and slow down production. Clean layouts print faster and stay consistent.

Simple designs include:

- One-color logos

- Small patterns

- Basic borders

- Simple shapes

Small designs still look professional when the box shape fits the product. Many modern brands choose simple layouts because customers like clarity. Clean prints improve shelf visibility. Simple prints also help when logo changes happen because changes cost less when artwork stays small.

Nevada shops that sell beauty products often use soft color palettes and light text for their custom boxes wholesale. This reduces ink use and keeps cost low. A good design always works well with box shape. Simple layouts stay timeless and easy to update.

Tip 5: Match the Box to the Product Size

Box size matters. A tight fit cuts shipping cost. A loose fit raises price because it uses more board and more filler. A tight fit also stops items from shifting in transit. Good sizing reduces breakage and returns.

Key sizing steps:

- Measure height, width, and depth

- Add light room for padding

- Avoid large empty space

- Match shape to product

A tight fit creates strong brand appeal because customers feel care in the unboxing moment. A box that fits well also stacks neatly in storage. A neat stack cuts warehouse time and reduces floor clutter.

Nevada shops that ship tech accessories often choose slim mailer boxes because slim boxes fit shelves better and lower mailing fees. Careful sizing also lowers weight, and lower weight saves money for all online sellers.

Tip 6: Count Shipping and Handling in the Full Budget

Shipping cost changes total spending more than many buyers expect. A strong box with light weight often costs less overall. A heavy box with strong walls costs more to ship. Using less space in shipping cartons also lowers cost. Shipping carriers charge more when packages take up too much room, even when they weigh little.

Good shippers choose materials that give enough strength without extra weight. Many Nevada sellers ship long distances, so light boxes help them stay competitive. When shipping zones change, cost changes too. A well-planned box shape lowers dimensional weight and protects profit margins. Good planning lowers wastage and prevents product damage.

A strong shipping plan builds trust with customers because customers receive packages without dents, tears, or crushed corners. Happy customers return for new orders.

Tip 7: Work With Local Nevada Suppliers When It Helps

Local Nevada suppliers offer fast service and quick support. Nevada holds a growing number of small packaging teams and printing shops. These teams offer short lead times and direct contact. Local sourcing also cuts freight cost.

Local support helps in several ways:

- Better communication

- Shorter delivery times

- Lower shipping fees

- Easier sample checks

- Faster reprints

Local options also help small sellers who want tight control over print colors and box shapes. Local shops help with revisions, and revisions often cost less when done nearby. Shipping damage stays low when Custom Boxes Nevada travel shorter distances.

Local sourcing also builds local partnerships. Strong local systems support long-term product lines and help Nevada companies grow in crowded markets.

Tip 8: Understand Minimum Order Quantity (MOQ)

Most manufacturers set MOQs for Custom Boxes in Nevada because they need to set machinery, cut dies, and prep materials. Many suppliers ask for at least a few hundred units.

MOQs create structure for:

- Setup costs

- Tooling cuts

- Printing plates

- Labor planning

Buyers should pick MOQs that match demand. A new business with unsure sales may choose semi-custom options. Semi-custom options use ready-made box shapes with simple logo prints. This lowers risk and cost. High MOQs work well for large sellers that ship thousands of units each month.

Nevada brands that grow fast often switch to bigger MOQs because bigger MOQs lower cost per box. Growth brings stability, and stability brings better margins.

Tip 9: Match Quality to Brand Image

Every product carries a brand story, and the box must reflect that story. High-end products need stronger boxes with smooth finishes. Budget products need simple boxes to keep pricing fair. Good packaging choices match the product value.

A brand with a premium look often uses rigid boxes. A brand with eco goals often uses custom kraft boxes. A trendy brand uses bright colors and bold shapes. A simple brand uses soft colors and neat lines.

Good quality builds trust. Poor quality hurts sales. A good box shape, feel, and weight create a lasting memory for customers. A strong brand message always starts with strong packaging choices.

Nevada sellers in the gift market often choose thicker materials because customers reuse these Custom Boxes Nevada. Reuse spreads brand impact, and reuse reduces waste.

Tip 10: Plan Packaging Early in Product Development

Good teams plan Custom Packaging in The Silver State early so the box supports production, shipping, storage, and marketing. A clear idea of box size and material helps creators plan the whole product journey.

Early planning supports:

- Color choices

- Logo placement

- Product protection

- Shelf display

- Shipping systems

A last-minute order creates stress and raises costs. Early planning avoids delay because the team orders samples and checks fit before mass production starts. Early planning also helps marketing teams prepare photos and ads.

Nevada product makers who build holiday items often plan months ahead because holidays raise demand. Early planning keeps them ready for busy seasons.

Tip 11: Choose Eco-Friendly Materials When It Supports Customer Values

Eco-friendly boxes grow in popularity. Customers like recycled material, soft kraft colors, and biodegradable choices. Eco Custom Boxes Nevada cost slightly more at times, but they bring strong brand loyalty.

Eco choices include:

- Recycled kraft

- Recyclable board

- Biodegradable pulp

- Compostable corners

Eco materials also create strong storytelling. Customers see care in the texture, the color, and the natural look. Good eco packaging gives sellers a stronger image, especially online. Many Nevada stores use eco boxes for handmade soaps, natural cosmetics, or organic snacks. Eco-friendly packaging builds trust in health-focused markets.

When brands show care for nature, customers respond with repeat purchases. A strong eco story builds social value and long-term loyalty.

Tip 12: Look at the Entire Cost — Not Only the Box Price

Smart buyers check the full cost, not just the price per box. True cost includes design, print, setup, shipping, labor, and storage. A low box price can hide extra charges. A full cost plan shows the real picture.

Total cost includes:

- Material

- Print plates

- Cutting dies

- Shipping

- Warehouse space

- Returns from damage

- Labor time

Many Nevada sellers check cost per unit after including shipping and damage rates. Good packaging lowers damage, lowers returns, and keeps shoppers happy.

A full cost approach leads to smarter budgeting and clear cash flow. A small rise in material cost sometimes lowers shipping cost or reduces damage, which saves more money in total.

Cost Estimates for Custom Boxes NV

Here are rough per-box cost ranges you can expect, depending on volume and box type:

|

Order Volume / Box Type |

Estimated Cost (USD per box) |

|---|---|

|

Bulk corrugated mailers (5,000+) |

$0.50 – $1.20 |

|

Folding carton (medium volume) |

$0.80 – $2.50 |

|

Rigid gift box (premium items) |

$3.00 – $5.00 (bulk); up to $8–$12+ (small runs) |

|

Small custom box (short run, basic) |

≈ $1.50–$3.00 |

Bonus Tips to Buy Custom Packaging in Nevada

Here are more simple ideas that support smart buying decisions:

- Pick a supplier with flexible design help

- Choose samples before large orders

- Track shipping zones

- Test box strength with real products

- Use volume charts to plan yearly demand

Nevada companies with many online sales gain from these systems because online orders rise and fall fast. Good systems smooth out these swings and keep orders steady.

Order Custom Boxes Nevada Today

Ready to wow your company by means of packaging that defends, advances, and amazes? Whether you need eco-friendly materials, eye-catching printing, or protective inserts, crafting Custom Boxes Nevada is ideal for you. It offers fast, inexpensive, and fully customized packaging options fit your product and budget. Turn your vision into reality—your winning custom packaging in Nevada is closer than you think. Click now for a free quote and begin designing with The Packaging Company.

FAQs

How does order quantity change the cost?

- Large batches lower cost per unit.

- Small batches raise costs because setups take time.

- High-volume orders drop cost to near bulk rates.

- Big orders reduce shipping per box.

- Repeating orders with stable volume saves money over time.

What materials do most brands choose for packaging?

- Paperboard supports small retail goods.

- Corrugated boards support shipping.

- Kraft supports eco goals.

- Rigid boards support luxury goods.

- Light materials help with low shipping cost.

How can a buyer choose the right box before ordering a big batch?

- Measure the product carefully.

- Choose a snug fit.

- Pick the right strength.

- Test sample Custom Boxes Nevada with real items.

- Check shipping needs before placing orders.