Designing the best Compostable Frozen Food Packaging means you must match material, barrier strength, and disposal plans to how people store and throw away food. The market for eco food packs keeps growing and many brands move to compostable options to cut waste and win trust. In the United States, buyers expect clear proof of compostability and real test data before they switch suppliers.

Choose materials that satisfy industrial compost standards and degrade under appropriate circumstances in roughly 90 to 180 days. Track unit cost, shelf life in weeks, and seal strength in grams per centimeter so you can evaluate choices and choose the ideal match for your product line. Shoppers will know how to get rid of packs and composters will accept the material if you use simple symbols and clear labels.

10 Innovative Ideas to Design Compostable Frozen Food Packaging

1. Pick Certified Compostable Materials

Choose films, trays, and coatings that carry clear third-party marks and lab reports so buyers and composters trust your claims. Ask Biodegradable Food Packaging suppliers for numbers that show compost time in days and residuals after testing. Include tensile strength in MPa and WVTR in g/m²·24h on materials that comply with industrial compost criteria.

Maintain a small list of reliable polymers and fibers that are suitable for cold storage along with their compost time, tensile strength, and price per kilogram. Compare samples using those figures and justify decisions to waste partners and purchasers. Buyers approve more quickly and composters accept the stream with less sorting when you provide unambiguous figures.

- Key numbers: compost time 90–180 days; tensile strength 20–50 MPa; WVTR 1–10 g/m²·24h.

- Certs to ask for: third-party marks and lab reports.

- Buyers want: clear proof and sample data.

2. Build Strong Moisture And Oxygen Barriers

Choose barrier layers that withstand low temperatures because frozen food requires protection from moisture loss and freezer burn. Test WVTR and OTR at −18°C to verify performance and assess weight loss across 30 days for actual results. Use compostable barrier coatings, PLA blends, or coated cellulose with low WVTR values and consistent OTR under cold storage.

Record shelf life in weeks and use those numbers to set storage guidance on the pack and to plan shipping windows for retail and wholesale orders. Good barrier data lowers product returns and enables you to define sell by dates.

- Test targets: WVTR ≤ 5 g/m²·24h; OTR ≤ 10 cc/m²·day.

- Shelf life goal: 12–52 weeks depending on product.

- Sample tests: 30-day weight loss; 90-day oxygen ingress.

3. Test Freeze–Thaw And Reheating Cycles

Since people move frozen meals from freezer to oven or microwave, design Custom Food Boxes that tolerate thermal shock. After each of at least ten freeze–thaw cycles, inspect seals, film strength, and venting. Measure seal integrity in grams per centimeter and note any leaks or film fractures.

Test reheating by heating to common oven temps and by microwaving at typical power levels. Use test results to set consumer instructions and to decide whether to add vent holes, reinforced corners, or thicker film layers to survive real use. When you test thoroughly, you cut complaints and lower waste from damaged packs.

- Minimum cycles: 10 freeze–thaw cycles.

- Seal strength target: ≥ 300 g/cm peel strength.

- Reheat tests: oven to 180°C; microwave 800 W for 3–6 minutes.

4. Design Reliable Seals And Closures

Strong seals stop leaks during shipping and keep product quality high, so use heat-sealable compostable films and measure peel strength in grams per centimeter. Test seals under pressure and after cold storage to ensure they hold. Use consistent sealing temperatures and dwell times on the production line to avoid weak spots.

Check seal performance after vibration and drop tests that mimic transport. Record peel strength, burst pressure, and failure mode for each sample so you can set production tolerances and train operators. Good sealing reduces returns and keeps food safe through long supply chains.

- Seal metrics: peel strength ≥ 300 g/cm; burst pressure ≥ 1.5 bar.

- Transport tests: 1 m drop; 2 hours vibration.

- Production control: fixed temperature and dwell time per run.

5. Label Clearly And Explain Disposal

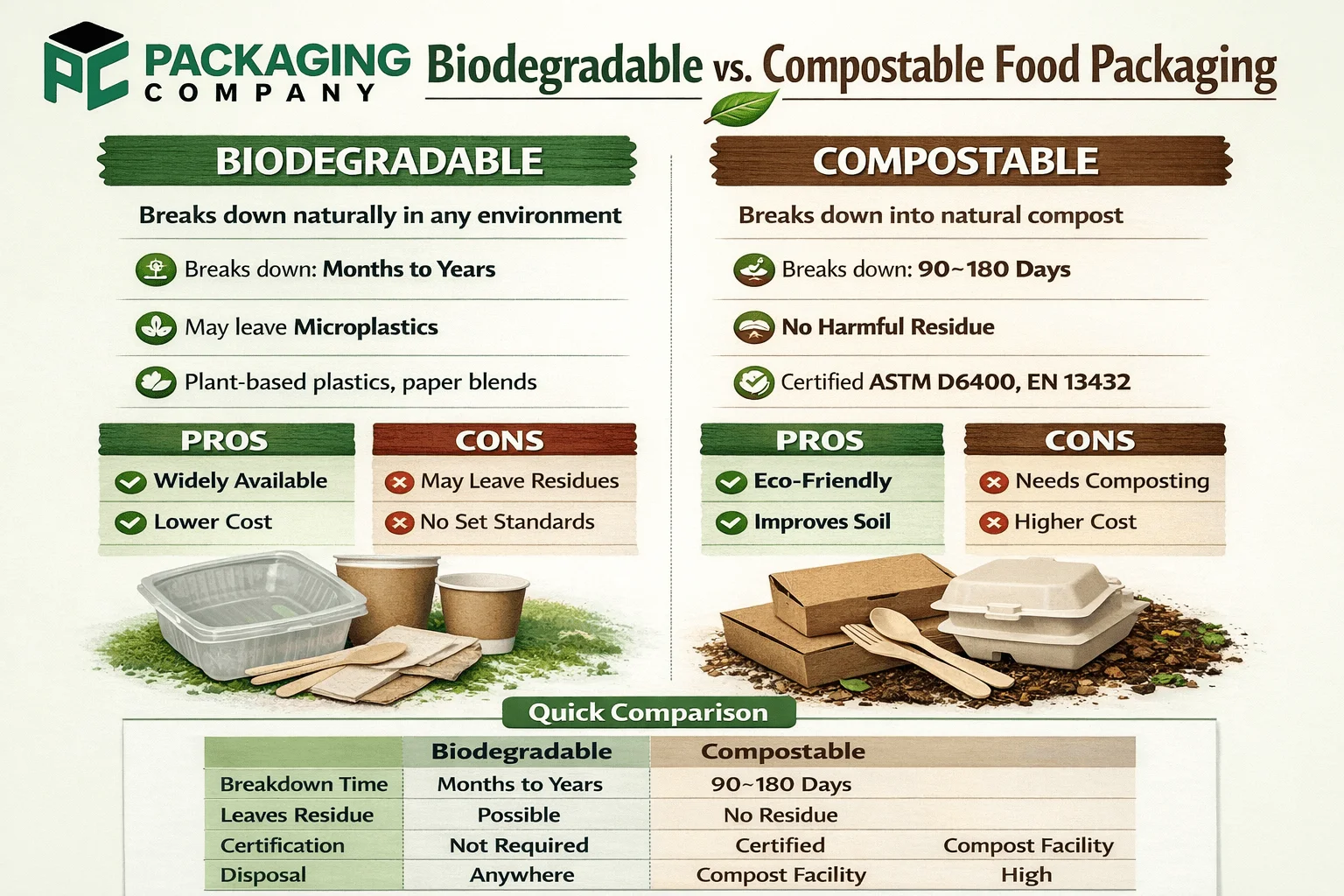

State whether the pack needs industrial composting or home composting. Describe the difference between biodegradable vs compostable food packaging. you should do it so that consumers know what to anticipate. On the pack, include the certification mark, the projected compost time in days, and basic disposal instructions.

Use short icons and one-line instructions to guide busy shoppers. Add storage temperature and reheating notes so people use the pack safely and avoid contamination in compost streams. Clear labels cut confusion and raise the chance that the pack reaches a proper facility.

- Label items: certification mark; compost time (days); disposal icon.

- Example numbers: 90–180 days industrial composting; home composting varies.

- Design tip: use 3 icons max for clarity.

6. Plan For Wholesale Sizing And Logistics

If you order Compostable frozen food packaging wholesale, standardize sizes and pallet patterns to cut handling costs and speed delivery. Ask suppliers about minimum order quantities, lead times in weeks, and sample programs so you avoid stock gaps. Common retail sizes help fit current shelves and help to minimize repackaging.

Track pallet-per-count carton counts, units per carton, and cubic meters per pallet to enable cargo and storage planning. Regular sizes enable you to get retail listings and reduce unit-level expenses.

- Logistics figures: units per carton 100–1,000; cartons per pallet 40–120.

- Lead time: Typically 7–12 days for bespoke runs.

- Minimum order quantity changes; anticipate 5,000–50,000 units for custom prints.

7. Verify Suppliers Before Purchase with Proof

Work with Compostable frozen food packaging suppliers like the Packaging Company who share lab reports, traceability, and production capacity so you can trust claims and avoid surprises. When you buy compostable food packaging bags, ask for certificates, WVTR and OTR numbers, and seal strength data. Check supplier audits and request sample runs to test on your line.

Use a brief supplier checklist covering lead time, MOQ, sample cost, test data, and certification. Save supplier test reports and batch numbers to enable you to trace any problem back to its source. Purchasing with evidence accelerates approvals and fosters customer and waste partner trust.

- Supplier checklist: certification; WVTR/OTR; seal data; lead time (weeks).

- Traceability: batch numbers and lab reports per shipment.

- Sample runs: test 100–500 units before full order.

8. Balance Cost With Life-Cycle Value

Though Compostable Bubble Mailers cost more per unit, they reduce landfill trash and can help to enhance brand worth. Compare alternatives using basic life cycle statistics: unit cost, projected compost diversion rate, and marketing lift. Determine cost per usage and include disposal savings if feasible.

Show purchasers the figures in a brief table specifying unit cost, shelf life in weeks, and compost time in days. Win internal clearances and create a strong business argument for changing using those numbers. Showing actual numbers helps stakeholders to grasp the compromises and quickly approve alterations.

- Compare metrics: unit cost; shelf life (weeks); compost time (days).

- Example: unit cost +20–50% vs standard plastic; diversion rate target 60–90%.

- Decision rule: pick option with best net value over 12 months.

9. Use Compostable Inks And Simple Printing

Select compostable inks. Also, stay away from non-compostable coatings or laminates. They impede composting. To help composters accept the pack and lower material complexity, keep print areas tiny. Where feasible, simplify compost streams and reduce cost by employing two- or one-color printing.

Test printed samples in compost conditions to confirm ink breakdown and record ink type, print coverage percentage, and any additives so you can show composters what you used. Simple printing makes the pack easier to compost and keeps your claims honest.

- Print limits: keep coverage ≤ 30% of surface area.

- Ink type: water-based, certified compostable inks.

- Test step: compost sample prints for 90 days and record residues.

10. Map End-Of-Life Routes And Partner Locally

Not every city accepts compostable packaging for food, so map local industrial composters and add clear disposal steps on the pack. Work with waste partners to set up collection routes and to track diversion rates in kilograms per month. Run pilot programs with a few stores to test collection and to measure how much of your pack reaches a composter.

Use pilot data to expand collection and to show proof to buyers and regulators. Local partnerships close the loop and prove your pack works in the real world. When you show diversion numbers, retailers and regulators support wider rollouts.

- Pilot metrics: diversion kg/month; contamination rate %; facility acceptance rules.

- Target: diversion ≥ 60% in pilot stores.

- Scale plan: expand after 3 months of stable diversion data.

Quick Comparison Table

|

Feature |

Compostable |

Biodegradable |

|---|---|---|

|

Standard tests |

ASTM/EN; third-party marks |

No single standard |

|

Typical end-of-life |

Industrial composter; 90–180 days |

Varies; no guaranteed time |

|

Consumer clarity |

High with clear label |

Often confusing without proof |

Market Graph

Market Growth

Eco packaging market index by year (base 2019 = 40)

This simple chart shows steady growth and rising interest in compostable options. Use it to explain why you should test and launch now.

Start With Samples And Tests

Order samples, run freezer and reheating trials, and ask Compostable Frozen Food Packaging suppliers for certificates and lab reports so you can launch with confidence. Work with partners who share test data, show lead times in weeks, and help you map local composting routes. When you test and document results, you reduce risk, win buyer trust, and make a real step toward lower waste. To get the right custom packaging, always rely on the Packaging Company.

FAQs

How fast does compostable packaging break down?

- Industrial composting: about 90–180 days under controlled heat and microbes.

- Home composting: times vary and often take longer.

- Ask suppliers for lab data that shows expected days to breakdown and residuals.

- Use those numbers on your label to set customer expectations and to reduce contamination.

What’s the difference between biodegradable and compostable packaging?

Something biodegradable degrades gradually throughout time. It has no usual schedule or test, though. Compostable means the substance fits current criteria. Under some conditions, it also breaks down into compost in a fixed period of time.

Where can I buy compostable food packaging bags?

Buy from vendors who show certificates and lab reports. Ask for sample runs and test data. Check lead times in weeks and minimum order quantities so you can plan inventory. Use a supplier checklist to compare offers and to speed approvals. Test samples on your line before you place a large order so you avoid production delays.

Do compostable films resist moisture?

- Some PLA/cellulose blends show good moisture resistance at low temps.

- Check WVTR numbers in g/m²·24h to compare films.

- Run 30-day weight loss tests at −18°C to confirm performance.

- Use barrier data to set shelf life and shipping windows so product quality stays high.

Who supplies wholesale compostable frozen packaging?

Large converters and niche makers offer wholesale options. Ask about MOQ, lead time in weeks, and sample programs. Compare suppliers on certification, test data, and production capacity.

Do compostable packages need special inks?

- Yes: use water-based, compostable inks.

- Avoid non-compostable varnishes and laminates.

- Test printed samples in compost conditions to confirm ink breakdown.

- Keep print coverage low to reduce complexity and help composters accept the pack.

- Record ink type and print coverage for composters and auditors.

Do compostable packages release microplastics?

Certified compostable materials avoid persistent plastics when they meet standards. Ask suppliers for chemistry data and lab reports that show breakdown products. Use test data to reassure buyers and composters and to avoid claims that could harm your brand.