Every day, US businesses and people send out boxes. In 2024, USPS handled over 6.9 billion parcels. UPS moved 5.6 billion packages, and FedEx processed 4.8 billion. To avoid surprise fees, you need to know How to Measure Box Dimensions?

E-commerce drives this volume. The US saw $1.05 trillion in online sales in 2023. That growth pushes carriers to audit package sizes and weights. If you submit an under-report, you face extra charges and delays.

Carriers use length, width, and height to set rates. They also check girth for large shipments. Mistakes here can double your cost. This guide shows terms, tools, and steps to measure right. It is ideal for sellers on eBay and Amazon, and anyone who ships gifts. You will get exact methods for tape measures, digital tools, and best rounding rules. No guessing. Just simple, proven techniques.

How to Measure Box Dimensions? 11 Proven Ways

By following these instructions, you cut packing time and avoid audits. You keep customers happy with predictable costs and on-time delivery. Let’s start by defining key terms.

1. Understanding Box Dimension Terminology

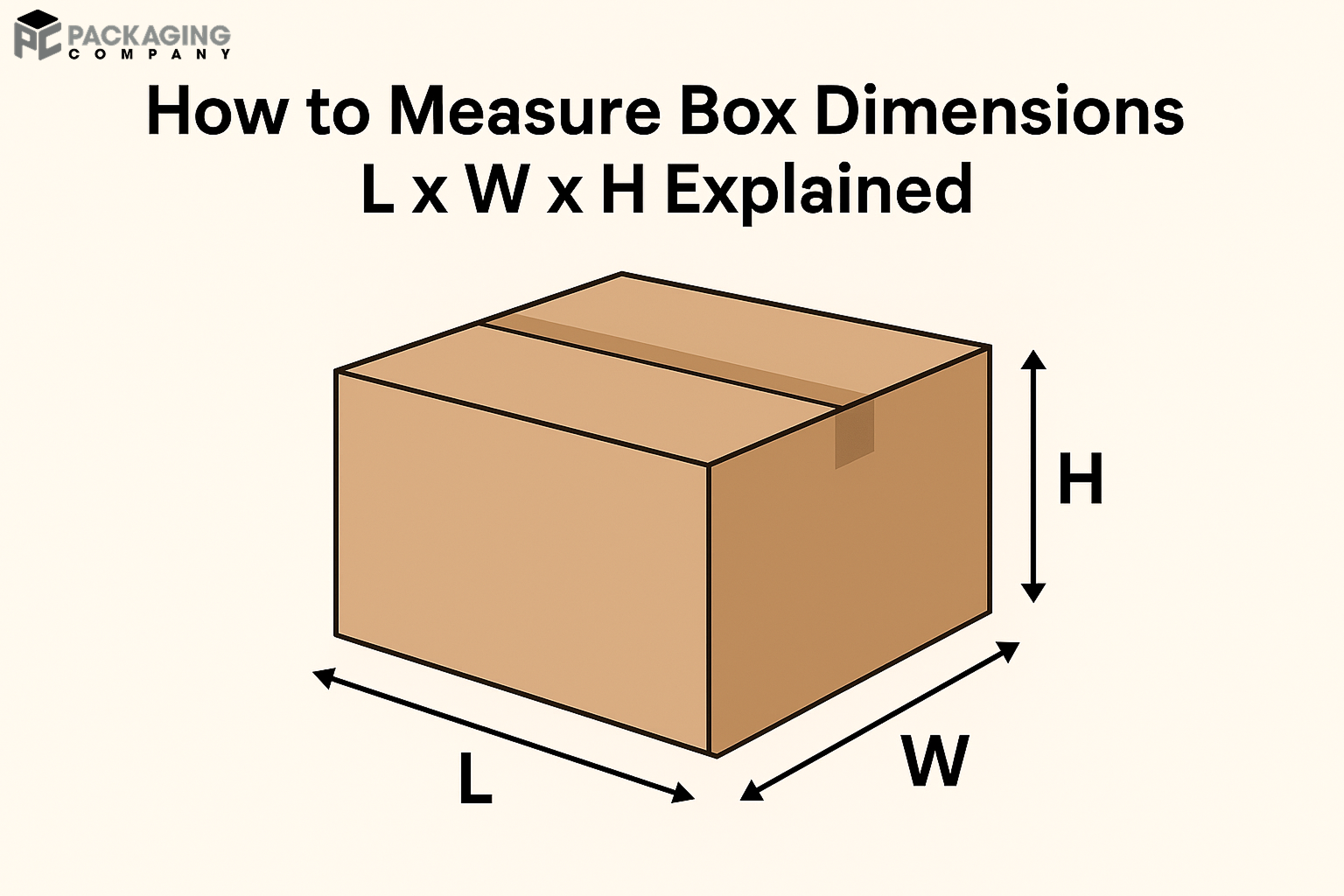

When you pack a box, you use three numbers: length, width, and height. Length runs along the longest side. Width measures the side across from length. Height is the vertical height when you stand the box up. Write them as L × W × H so carriers see it clearly.

You always measure with the Custom Cupcake Boxes closed. Carriers charge on outside size, so tape and flaps count. Inside size matters when you pack. You choose the right fillers to protect your contents, but you bill via outside numbers.

Many shippers ask how to measure a box dimensions step by step. They worry about flaps, tape, and bulges. Keep your box neat, and record numbers exactly. That way, you avoid reweighs and extra bills.

2. Essential Tools for Measuring a Box

You need a good tape measure that fastens at the end. A 25-foot model works for most cartons. A stiff metal ruler helps on small boxes. Hold your tool tight and level. That ensures straight lines from one corner to the other.

Digital scales give you exact weight. Carriers compare weight and volume to pick the higher charge. A bubble level or flat table stops bulges from hiding extra space. Bulges push out box sides and add to your measurements if you don’t spot them.

Smartphone apps let your camera map edges and give you box size instantly. You also can buy Bluetooth calipers that clamp the corners and send readings to your phone. These tools are ideal for understanding how to measure box dimensions for shipping fast and foolproof.

3. Preparing Your Box for Measurement

First, seal your box. Fold flaps down and tape them flat. Avoid piling tape on one spot. Thick layers push out the walls and change your numbers. A neat seal gives a true picture of your box size.

Next, remove loose tape ends and stray labels. Press down any bumps or wrinkles. If your box bulges from contents, repack it or use a stronger carton. You want true flat surfaces so you record honest dimensions.

Practice how to measure dimensions of a box for shipping by checking several places on each side. If one spot reads higher, use that number. Carriers look for the largest measure, not an average.

4. Calculate Length, Width & Height

Follow these steps in order. You capture each dimension correctly and avoid guesswork. Keep your box on a flat, level surface.

Determine Length

- Lay the box so its longest side faces you.

- Hook the tape at one corner of the base and stretch to the opposite corner.

- Record the largest number and round up to the next full inch.

Measure Width

- Rotate the box so the side across from length faces you.

- Pull the tape from one edge to the other.

- Write down the highest reading in inches.

Check Height

- Stand the box upright on its base.

- Place the tape at the bottom edge and extend to the top edge.

- Note the highest number and round up.

Repeat each measurement twice. If you get two different numbers, go with the higher one. This habit avoids costly corrections when carriers audit your entry. Many carriers charge reweigh fees over $15 if they find mismatches.

Finish by writing your dimensions as Length × Width × Height on your shipping forms. Accurate numbers prevent surcharges and delays.

5. Recording and Rounding Rules

After measuring, record your numbers correctly.

- Always round up each dimension. If you read 10.2 inches, you write 11. Carriers never allow rounding down.

- Use inches for US shipments. Do not switch between inches and centimeters.

- Note small variances. If a corner bulges by ¼ inch, record the larger reading.

Carriers penalize errors heavily. They might charge up to $28 for a size correction. Make a habit of writing “L×W×H” with no spaces to avoid data-entry errors. This step completes your how to measure a box dimensions process.

Keep a log of past labels. Comparing entries helps you spot trends, like consistent over-measuring on certain box sizes. That insight lets you choose better cartons.

6. Calculating Volume and Dimensional Weight

Carriers bill on whichever is higher: actual weight or dimensional weight.

Volume tells you how much space your box occupies. Calculate it:

- Volume = Length × Width × Height

Next, find DIM weight. Divide volume by a carrier’s divisor (often 139 for US ground). For example, a 24 × 12 × 8 inch box has 2,304 cubic inches. Divide 2,304 by 139 to get 16.6 pounds. Carriers round that up to 17 pounds.

They compare your actual weight to the DIM weight. If you ship a single book weighing 8 pounds in that Custom Cookie Boxes, you pay as if it weighed 17 pounds. That’s why you must record the true size.

When you master How to Measure Box Dimensions? you cut wasted chargeable pounds and avoid costly surprises. Then you know if you need a smaller box or a different service level.

7. How to Measure Girth and Total Package Size

Girth measures the distance around the narrowest part of your box. Calculate girth:

- Girth = 2 × (Width + Height)

Then add length to girth to find total package size:

- Total = Length + Girth

Most UPS and FedEx services cap this at 165 inches. USPS limits retail ground to 108 inches total. If your box exceeds these limits, you pay an oversize surcharge.

Follow how to measure dimensions of a box for shipping steps to avoid penalties. Accurate girth calculations help you stay within carrier limits and sidestep extra fees.

8. Carrier-Specific Measurement Guidelines

Each carrier sets its own rules. Learn them to save money.

USPS

- Offers free flat-rate boxes you can reuse.

- Charges DIM weight only for certain international services.

- Requires external measurements, including tape and flaps.

UPS

- Uses a DIM divisor of 139 for ground shipments.

- Adds extra charge if Length + Girth exceeds 130 inches.

- Rounds each dimension up to the next whole inch.

FedEx

- Applies DIM weight on most parcels.

- Caps combined length and girth at 150 inches for ground.

- Uses a 139 divisor on FedEx Ground.

Check each carrier’s website for updates. Follow how to measure a box dimensions tips to match their criteria exactly. That practice saves you headaches and money.

9. Common Mistakes When Measuring Box Dimensions

Avoid these errors to keep costs low.

Measuring bulges

- Do not let tape or bumps push out a side.

- Flatten flaps and tape before you measure.

Mixing inside and outside measurements

- Carriers charge on outside size.

- Inside dimensions only matter for packing.

Skipping double-checks

- Measure each dimension twice.

- Use the higher reading.

Wrong rounding

- Never round down.

- Always move up to the next inch.

Ignoring carrier rules

- Each carrier has unique size limits.

- Read their latest guidelines.

When you avoid these mistakes, you master how to measure the dimensions of a box and ship without surprise charges.

10. Advanced Techniques & Tech for Accurate Measurements

If you ship high volumes, upgrade your toolkit.

Laser Distance Tools

- Aim a laser at one corner and sweep to the opposite corner.

- Get a clear digital readout of your box size.

Automated Measurement Stations

- Scan boxes on conveyor belts for instant data.

- Integrate with warehouse software.

Bluetooth Calipers and Apps

- Clamp the corners of your box with digital calipers.

- Transfer measurements directly to your order system.

Smartphone apps that map edges with your camera speed up how to measure a box dimensions tasks in real time. These systems cut human error and let you process hundreds of packages per hour.

11. Cost-Saving Strategies Through Proper Measurement

Accurate measurements lead to lower bills.

Choose Right-Sized Boxes

- Match box volume to product size.

- Avoid empty space and weight penalties.

Use Dimensional Discounts

- Compare actual weight and DIM weight; pay the lower cost.

- Use flat-rate boxes for heavy items under 20 pounds.

Leverage Carrier Services

- USPS regional rate boxes can cost less than flat rates for short drives.

- UPS Simple Rate offers a single rate for boxes under set dimensions.

Short But Comprehensive Guide to Box Dimensions

|

Section |

Key Points |

|---|---|

|

1. Terminology |

L×W×H; outside size for billing; inside size for packing |

|

2. Essential Tools |

Tape measure; metal ruler; digital scale; level; measurement apps |

|

3. Box Preparation |

Seal flaps flat; smooth bumps; repack bulges; double-check surfaces |

|

4. Measuring L, W & H |

L = longest side; W = adjacent side; H = vertical; round up; repeat |

|

5. Recording & Rounding |

Always round up inches; use inches; record highest; write L×W×H |

|

6. Volume & Dimensional Weight |

Volume=L×W×H; DIM weight=Volume÷divisor; compare to actual weight |

|

7. Girth & Total Package Size |

Girth=2×(W+H); Total=L+G; respect carrier size caps |

|

8. Carrier-Specific Guidelines |

USPS flat-rate/international rules; UPS/FedEx DIV139 & girth caps |

|

9. Common Measurement Mistakes |

Bulges; inside vs outside; skipping double-checks; wrong rounding |

|

10. Advanced Measurement Technologies |

Laser tools; automated scanners; Bluetooth calipers; edge-mapping apps |

|

11. Cost-Saving Strategies |

Right-size boxes; use DIM vs actual weight; flat-rate/regional rates |

Slash Your Shipping Costs | Start Measuring Smarter Now!

By using these techniques regularly, you eliminate the dead cubic inches and prevent dimensional-weight additions. Even a few tweaks to your process will save you thousands of dollars a year. Still confused? Contact our packaging experts at the Packaging Company to know How to Measure Box Dimensions?

FAQs

Should I measure internal or external box dimensions?

Measure internal dimensions first, in case you are interested in the size of your product in relation to the inside. The usable space is provided by internal length, width and height. The exterior dimension is important in computing shipping rates or pallet optimization since the carriers charge the fees depending on the outside dimension.

What tools do I need to measure box dimensions accurately?

- Tape measure or retractable steel tape for most applications

- Ruler or yardstick for small or shallow boxes

- Digital caliper for high-precision measurements

- Laser distance measurer for large or hard-to-reach boxes

- Dimensional scanner or mobile AR app for rapid industrial measurements

- String or flexible cord for irregular shapes

- Flat, stable surface to set the box level

- Pen and paper (or digital notes) to record each measurement

Which units should I use for box measurements?

- Inches or centimetres, depending on your regional or carrier requirements

- Always stick to one system to prevent unit conversion errors

- Use millimetres for high-precision packaging design

- Record decimal places clearly (e.g., 12.5 in or 31.8 cm)

- Convert consistently if you switch between metric and imperial

How much clearance should I allow for padding materials?

- Add 1–2 cm (around 0.5–1 in) on each side for bubble wrap or foam

- Include extra height if stacking padding on top and bottom

- Factor in any rigid inserts or dividers you plan to use

- Check padding manufacturer specs for recommended thickness

- Always measure after padding is in place for final box choice

How to Write Box Measurements Correctly?

- Write dimensions as L×W×H (no spaces)

- List the longest side first

- Measure the closed box (include tape/flaps)

- Take two readings; record the larger

- Round up every measurement to the next inch

- Use inches only; don’t mix units

- Keep a log of past entries for consistency

How to Get the Volume of a Box?

- Measure L, W, H in the same unit

- Round up each value

- Calculate volume: L × W × H

- Result is in cubic units (e.g., inches³)

- Convert to feet³: divide by 1,728