Dry Ice Shipping Boxes

Packaging Company builds strong, insulated and temperature-controlled dry ice shipping boxes in bulk that keep frozen goods cold during shipping and help brands grow sales and keep customers happy.

Buy Dry Ice Shipping Boxes that Keep Food Safe in Transit

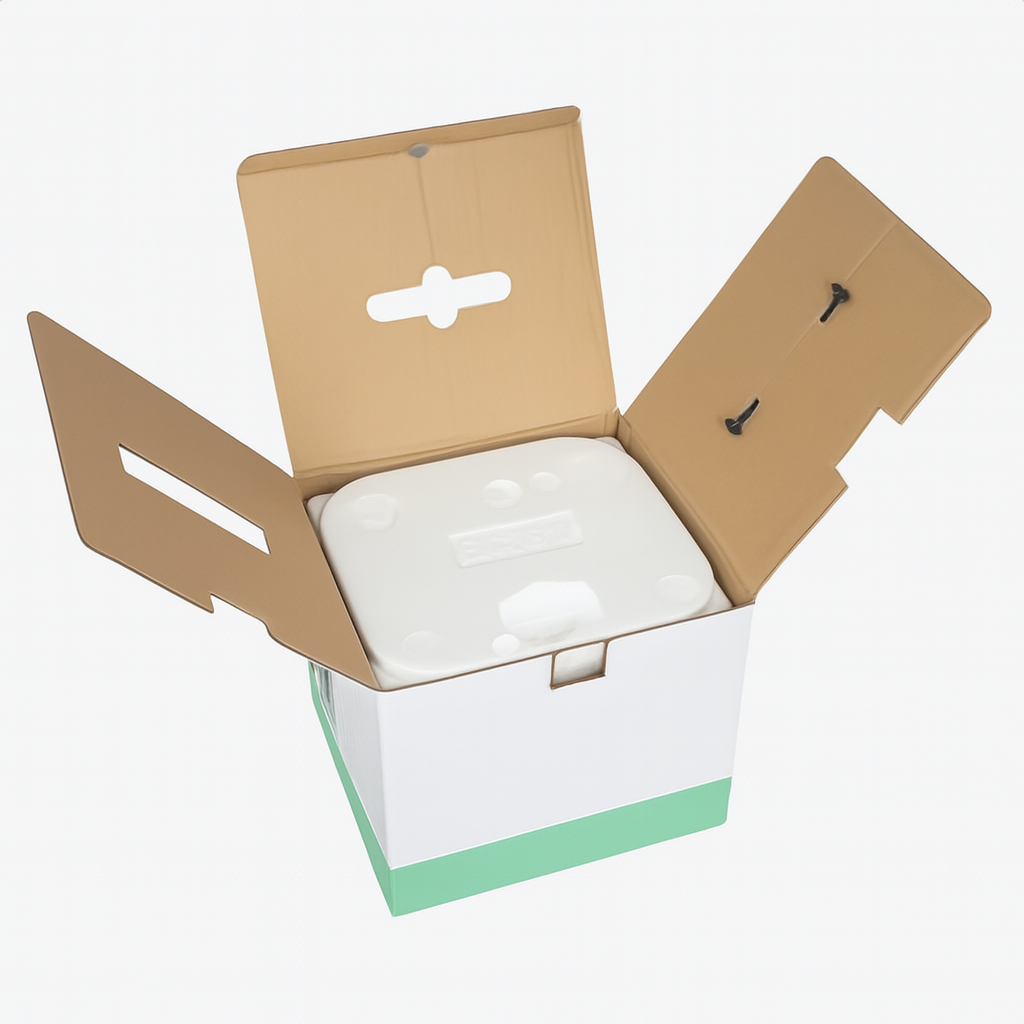

Temperature control starts with the right materials and layout of custom Dry Ice Shipping Boxes we deliver. Layers of insulation, secure seals, and a dedicated dry ice pocket help maintain low temperatures for the hours or days your shipments travel, supporting cold chain integrity for frozen foods during transit across varied climates. Tests show consistent hold times, so your products arrive in the expected condition and your promise holds true.

We test boxes with common carrier routes and packing scenarios to match what happens in the field rather than ideal conditions. These boxes use smart insulation and space for dry ice so items like seafood, meal kits, and ice cream reach buyers chilled and ready to enjoy, while the design supports dry ice and Candle Shipping Boxes wholesale for reliable delivery across the USA.

Clear packing steps and visible fill lines speed up training and reduce mistakes. When packers can work fast and correctly, your fulfillment center meets deadlines more easily and handles peak days without chaos. Our support materials explain dry ice amounts and safe handling, so staff follow rules and operations stay smooth.

Compliance, Safety, and Carrier Fit

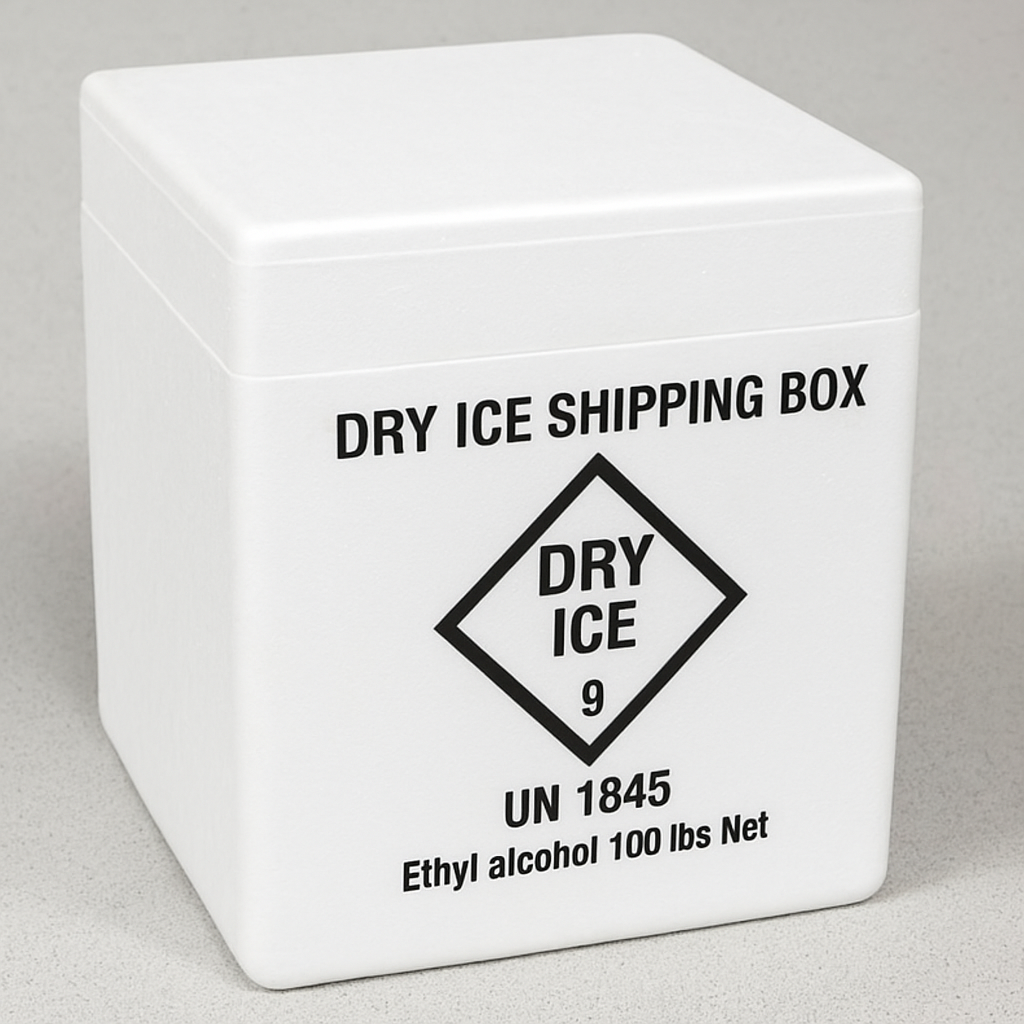

Dry ice moves under strict rules, so you need packaging that supports safe handling and clear labeling. Our custom Dry Ice box packaging wholesale includes room for hazard markings and step-by-step packing instructions that follow carrier guidelines for DOT and airline dry ice shipments, which helps avoid delays and fines while keeping staff safe. We provide the documents and labels your handlers need to meet regulations every day.

Design for carriers’ matters because size and weight drive cost and routing speed. We size boxes to meet major carrier limits and common pallet patterns so carriers accept the shipment without extra fees. Better carrier fit reduces rejected parcels and keeps delivery timelines predictable across coast-to-coast routes in the USA.

- Key compliance items to include: hazard labels; packing checklists; carrier-accepted dimensions.

- Carrier compatibility tips: choose standard box sizes; verify weight tiers; plan pallet patterns.

- Safety steps for staff: use gloves and eye protection when handling dry ice; follow ventilation guidance; secure closures properly.

- Documentation we supply: packing best practices; dry ice quantity charts; labeling templates.

Cost Savings, Sustainability, and Operational Gains

Our smart dry ice packaging in USA lowers costs by using materials and shapes that keep items cold with less dry ice and less waste. When boxes hold temperature well, you need fewer product replacements and face fewer refunds, which improves margins. We design to balance performance with an affordable per-shipment cost so brands scale without losing profit.

Choosing recyclable liners and responsibly sourced materials helps brands sell to eco-minded buyers while keeping the cold chain strong. Sustainability should not compromise thermal hold, and our selections keep both goals aligned. Transparent claims about materials and recycling encourage buyers to see your brand as responsible and modern. Standard box sizes and pack trays speed packing and reduce errors, which saves labor costs and helps you meet daily targets.

- Cost-focused advantages: lower dry ice use; fewer spoiled shipments; better margins per order.

- Sustainability actions: use recycled board; recyclable liners; clear disposal instructions.

- Operational wins: faster packing times; fewer packing errors; easier training for staff.

- Inventory control tips: standardize SKUs; track dry ice usage per package; optimize pallet loading.

Branding and the Unboxing Moment

Packaging Company builds these details into the pack so brands benefit from higher retention without extra work. Training and simple reference guides help packers and drivers follow safe practices, preventing spills and lowering risk. Clear, consistent procedures protect workers and reduce liability, and our team stands ready to answer questions so your operations move forward without surprises.

Our boxes keep temperatures steady through long trips and help reduce returns and complaints, which raises reviews and repeat orders. Clear, honest claims help brands gain trust and long-term loyalty from shoppers who check labels. We stand ready to help with design tweaks, packing guidance, and supply planning for your custom shipping boxes in USA so your frozen products ship safely and sell better.

- Benefits of branded dry ice shipping packaging boxes: visible brand exposure; perceived premium quality; higher repeat purchase rates.

- Design elements to include: high-resolution logo; clear handling icons; care and thaw instructions.

- Customer-focused inserts: simple usage tips; promotional codes; recycling guidance.

- Sustainability signals: recyclable liners; responsibly sourced materials; messaging that matches product values.

Get branded Dry Ice Shipping Boxes in USA made for your product and boost repeat purchases.

| Box Style | Dry Ice Shipping Boxes |

| Dimension (L + W + H) | All Custom Sizes & Shapes |

| Quantities | No Minimum Order Required |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Scored, Perforation |

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | 4 – 8 Business Days, RUSH |

| Shipping | FLAT |

Get Free Quote

Get a free quote on any packaging project instantly, no matter how complex it is.

Material Selection

We suggest the perfect packaging material for your box once you select the box style.

Artwork Preparation

Share your artwork & design; if not, we will design it based on your suggestions.

Start Production

Once your artwork is approved, we'll begin production. We will support you at every step.

Small packs will take approximately 24 hours, medium packs will need around 48 hours and large well-insulated boxes can take up to 72+ hours when you add the right amount of dry ice weight and we pack the box well.

Yes! Write on each parcel either Dry ice or Carbon dioxide solid, include UN 1845, include net weight in kilograms and add handling notes to allow the carriers and handlers to view the hazard at a glance.

Yes, but use leak-proof bags and absorbent material because liquids can cause damage and reduce insulation effectiveness; we recommend double-bagging fragile liquids.

Cushion fragile items with breathable padding, keep dry ice separated with a barrier, and leave at least 2 inches of insulation around the product so it survives handling.

No. Dry ice remains at -78.5C hence wear insulated gloves and use tongs when handling to prevent the risk of short exposure and frostbite.