Picking the correct box improves storage, shipping, and display. For this purpose, knowing Shoe Box Dimensions is vital as it enables American readers to make informed decisions quickly. Common sizes are covered in the guide together with how to measure shoes and boxes, packaging advice, material options, cost drivers, sustainability, and how to select or order the proper box for every shoe style.

A correct box size improves the customer experience and cuts shipping costs. A well-fit box protects the shoe and looks good on a shelf. A box that sits too loose wastes space and raises parcel fees.

The Ultimate Guide to Shoe Box Dimensions

Retailers, online sellers, and anyone storing shoes save time and money when box sizes match the shoe. Thus, knowing the Shoe Box Dimensions is essential for which this guide is useful.

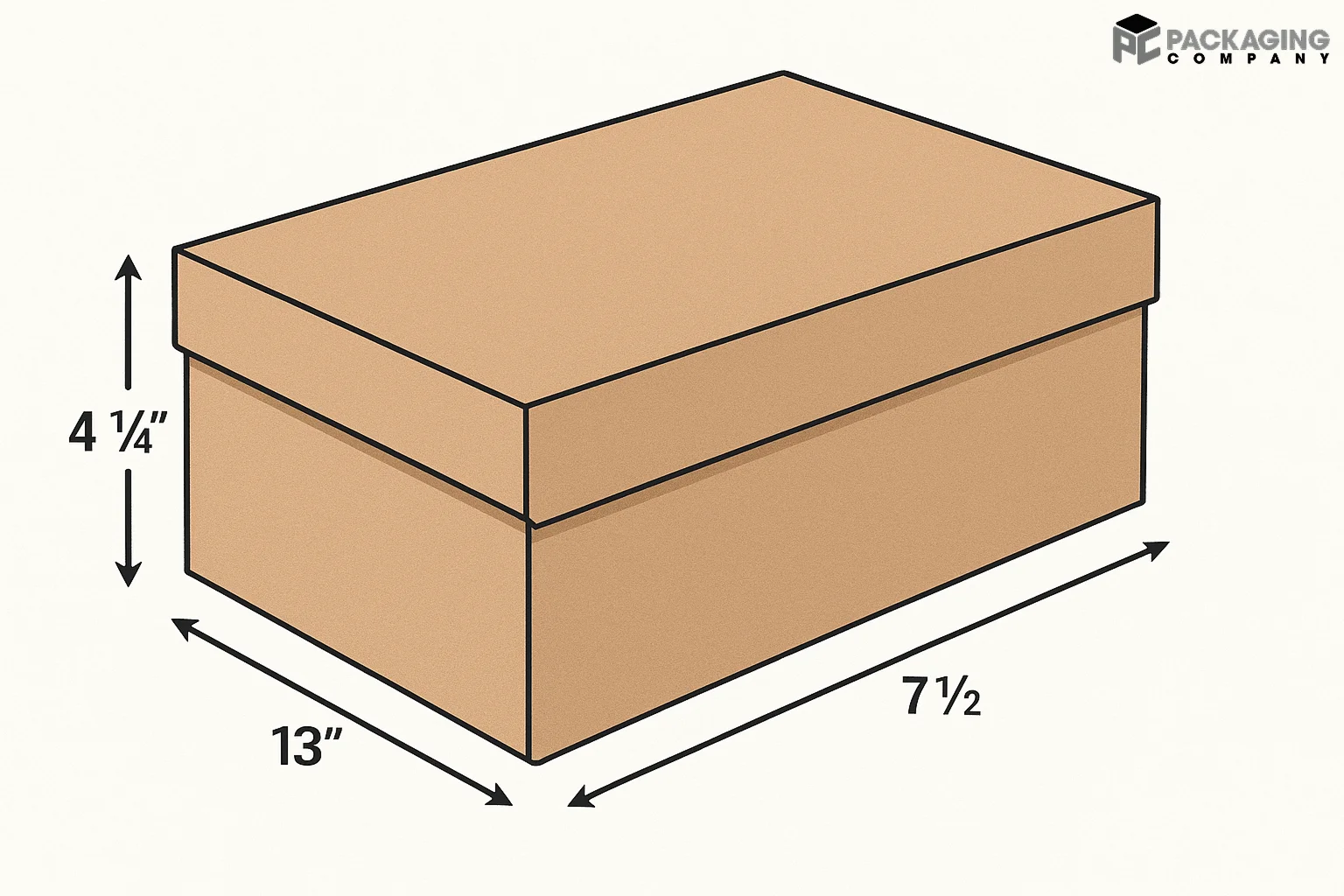

How to read box measurements?

Box sizes show three numbers: length, width, and height. Most makers list external measurements. Some list inside numbers, so always check the label before ordering. Length runs along the longest side. Width measures the shorter top side. Height measures from the base to the lid. Measure shoes lying flat and add room for tissue or paper. Add more space for heavy padding or molded inserts.

- Length (L): the longest side of Custom Shoe Boxes

- Width (W): the shorter top side

- Height (H): the distance from base to lid

Measure carefully to avoid surprise fit problems and extra shipping costs.

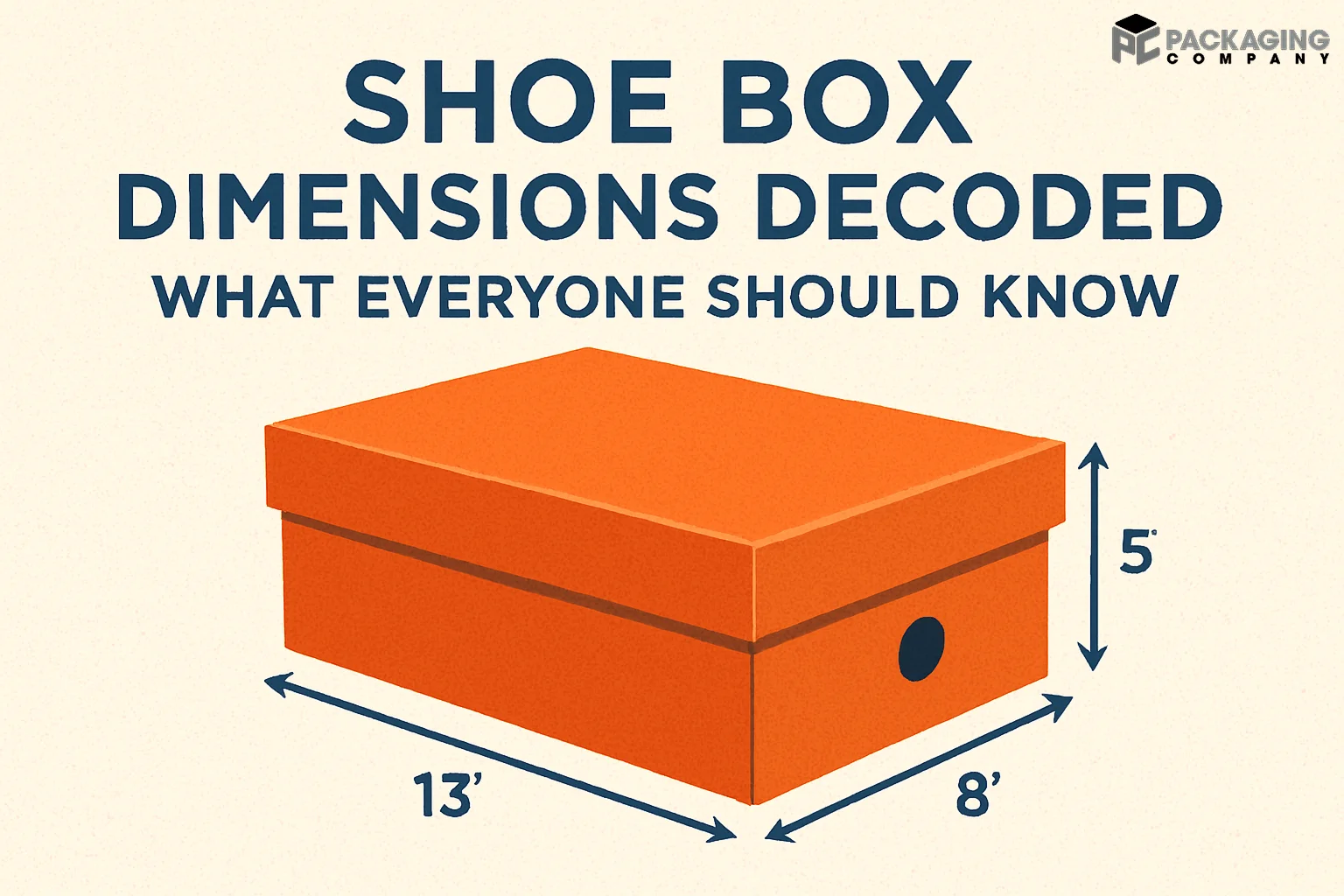

Common standard sizes

|

Shoe type |

Typical external dimensions (inches) |

Typical external dimensions (cm) |

|---|---|---|

|

Men's sneakers |

13 x 8.5 x 5 |

33 x 22 x 13 |

|

Women's flats |

11.5 x 7.5 x 4 |

29 x 19 x 10 |

|

Kids' shoes |

9.5 x 6.25 x 3.75 |

24 x 16 x 9.5 |

|

Boots (short) |

14 x 10 x 6.5 |

35.5 x 25.5 x 16.5 |

These sizes help pick a good starting point for most common shoes and prevent costly mistakes.

Design choices that change dimensions

Box style affects the final size. A rigid box gives a premium look and keeps shape well. A tuck-top box uses less height and fits under shelves more easily. Telescoping boxes can shrink shipping height for some shoes. Add vents for athletic shoes or a window for retail display. Each design choice changes the external measurements on order forms.

- Use inserts for premium shoes

- Add ventilation holes for athletic shoes

- Add a window for retail display

Always ask the supplier how design features change the listed size values.

Materials and weight basics

Different materials change both feel and weight. Thin cardboard keeps costs down for bulk shipping. Thicker board adds protection and gives a premium feel at retail. Laminates add shine and protection, but they add a thin layer of thickness. Corrugation grade also changes box stiffness and outer size slightly because of folds and seams. Choose material that suits the product and the shipping plan.

- Single-wall corrugate: light and cheap

- Double-wall: stronger for heavy shipments

- Rigid board: premium look and higher weight

Pick materials with an eye on carrier rules for dimensional weight so shipping stays affordable.

How to measure a shoe and a box correctly?

Measure the shoe and the box to make sure sizes match. Start with the shoe’s longest point and measure to the toe. Find the widest point across the shoe and measure that. Measure the tallest point to set box height. Add 0.5–1 inch of space for tissue and light padding. For boots or bulky winter shoes, add more height and length.

- Measure shoe heel to toe for length.

- Measure side-to-side at the widest point for width.

- After that, measure the tallest point for height.

- Add 0.5–1 inch for padding and tissue.

You must do a test pack with the real shoe before ordering hundreds of custom boxes wholesale.

Packing tips for shipping and storage

Armor the shoe for transport and keep the box tidy in storage. Wrap delicate materials in tissue paper. Place heavier shoes at the bottom when shipping pairs in the same box. Fill empty space with proper void fill to prevent movement. Use tape that holds but does not crush the box edge. Label the box so packers and customers can see size and SKU.

- Use tissue paper to reduce sliding

- Place heavier shoes at the bottom

- Wrap delicate materials separately

- Use proper void fill for stability

Small packing steps reduce damage rates and returns.

Sustainability and box size

Right-sized boxes have a reduced carbon effect and use less material. Search boxes that fit the shoes with little to no excess. When practical, pick recycled inks and recyclable boards. Stay clear of plastic inserts unless they offer a definite protective benefit. Little design adjustments reduce both waste and transportation expenses.

- Choose recyclable Custom Cardboard Boxes

- Design boxes to fit closely to reduce waste

- Minimize plastic inserts

- Use recycled inks and coatings where possible

- Consider box reuse or return programs

Consumers in the USA respond well to clear sustainability notes on packaging.

Tables for quick decisions

|

Purpose |

Recommended box type |

Typical dimension range (inches) |

|---|---|---|

|

Retail display |

Window top, rigid |

11–14 L; 7–10 W; 3.5–6 H |

|

E-commerce shipping |

Single-wall corrugate, snug fit |

12–14 L; 8–10 W; 4–6 H |

|

Long-term storage |

Rigid, stackable |

Variable; choose slightly larger for tissue |

These quick tables help match a box to the exact need, whether display, shipping, or storage.

Sizing chart by shoe category

|

Category |

Example shoe |

Best internal fit (inches) |

|---|---|---|

|

Athletic men's |

Running shoe |

12.5 x 8 x 5 |

|

Dress women's |

Heels/loafers |

11 x 7.5 x 4 |

|

Child |

Toddler shoe |

7.5 x 5 x 3 |

|

Boot |

Ankle boot |

13 x 9 x 6 |

Use internal fit as the target. Add the board thickness to estimate external dimensions.

Branding, unboxing, and customer perception

A well-fit box raises perceived value. Small boxes feel thoughtful and efficient. Big empty boxes feel wasteful and cheap. Embossing and spot UV stand out on rigid boxes. Tissues and stickers make e-commerce feel personal. Clear labels make returns easier. Align the box size with brand goals and practical needs.

- Embossing works well on rigid boxes

- Tissue and stickers work for e-commerce

- Clear labeling makes returns easier

A strong unboxing keeps customers happy and lowers complaints.

Cost drivers tied to dimensions

Carriers often charge by dimensional weight for large but light boxes. A box that looks big but holds light shoes can cost more to ship than a smaller heavy one. Minimize unused space to lower shipping fees. Avoid unnecessary tall boxes that push packages into a higher billing bracket. Make small adjustments to width or height and check carrier weight rules before finalizing box sizes.

- Reduce unused space to lower shipping fees

- Avoid unnecessary height increases

- Check carrier dimensional rules before ordering

These checks prevent unexpected shipping bills and improve profit per order.

Common sizing mistakes

Designers and sellers make predictable errors that cost money. One mistake comes from choosing boxes for looks rather than fit. Another mistake comes from ignoring carrier dimensional rules, which raises shipping bills. A third mistake comes from confusing internal and external measurements. Fix these problems by measuring shoes and validating sizes with carrier rules before ordering large runs.

- Designers pick a box by look, not by internal fit

- Sellers ignore carrier dimensional rules and pay higher shipping

- Teams measure external dimensions but order boxes keyed to internal size

Fix the errors with standard measurements and sample boxes.

Shipping checklist for shoe boxes

Create a clear checklist to lower mistakes in packing and shipping. Confirm whether the supplier lists internal or external dimensions and check carrier dimensional weight rules. Test pack a few SKUs and order box samples before committing to a large run. Label each box with SKU and size so packers pick the right box fast.

- Confirm internal vs external dimensions

- Check carrier dimensional weight rules

- Test pack several SKUs physically

- Order samples before a full production run

- Label corrugated boxes wholesale with size and SKU for packers

This checklist stops common mistakes and saves money over time.

How to Customize Shoe Boxes?

Add the following things in your shoe packaging for customization.

- Board and Material Thickness of 300–450 gsm SBS; corrugated (B, C, E flute) for shipping strength; 1.2 to 2.5 mm rigid board.

- Matte/gloss varnish, soft-touch lamination, spot UV, aqueous or thermal embossing for tactile branding define finishes and coatings.

- Among them are foils, metallic inks, debossing or embossing for a high-end feel, hot-stamp foil (gold/silver), and embellishment.

- For fit and safety, custom foam, cardboard, or paperboard inserts; die-cut viewing panels; and clear PVC or PET windows.

- Among the sustainable alternatives are recycled board, FSC-certified paper, soy-based inks, less printing, or mono-material design for recyclability.

- Full CMYK print; spot UV; 1–4 PMS spot colors; include product information, patterns, and trademarks.

- Usual dimensions for tuck-top, lift-off lid, magnetic closure, drawer; Change style: 30x20x10 cm (12x8x4 in); 35x25x12.5 cm (14x10x5 in); 40x30x15 cm (16x12x6 in).

- Functional add-ons include resealable closures, handles, hang tags, perforations for easy opening, QR codes, sizing/variant labels.

Boost Brand Value with Perfect-Fit Shoe Boxes

Ready to pick the right box for the product line? Check the shoe sizes, compare them to common standards, and choose a box that fits snugly. For help with custom sizes or expert review, contact a packaging specialist to optimize fit, costs, and presentation. Ask a top packaging partner like the Packaging Company to review Shoe Box Dimensions for each SKU to cut shipping, boost unboxing appeal, and raise brand value.