In the United States, custom Blister Packaging is one of the most trusted ways to keep products safe. The market for blister packs is worth over $4.2 billion, and it grows about 6.5% each year. Because they keep tablets secure, fresh, and simple to count, more than 70% of the pharmaceuticals produced in the nation are housed in blister packs. To prevent tampering and theft, custom blister packs are also used in electronic devices, toys, and batteries.

Many items need tamper-evident packaging; the FDA says; companies that violate these regulations risk losing millions of dollars in recalls. There are more than 1,200 blister pack suppliers and hundreds of blister pack companies across the U.S., and new packaging ideas shape how customers trust brands. Using custom blister packs not only keeps products safe but also builds trust in the market.

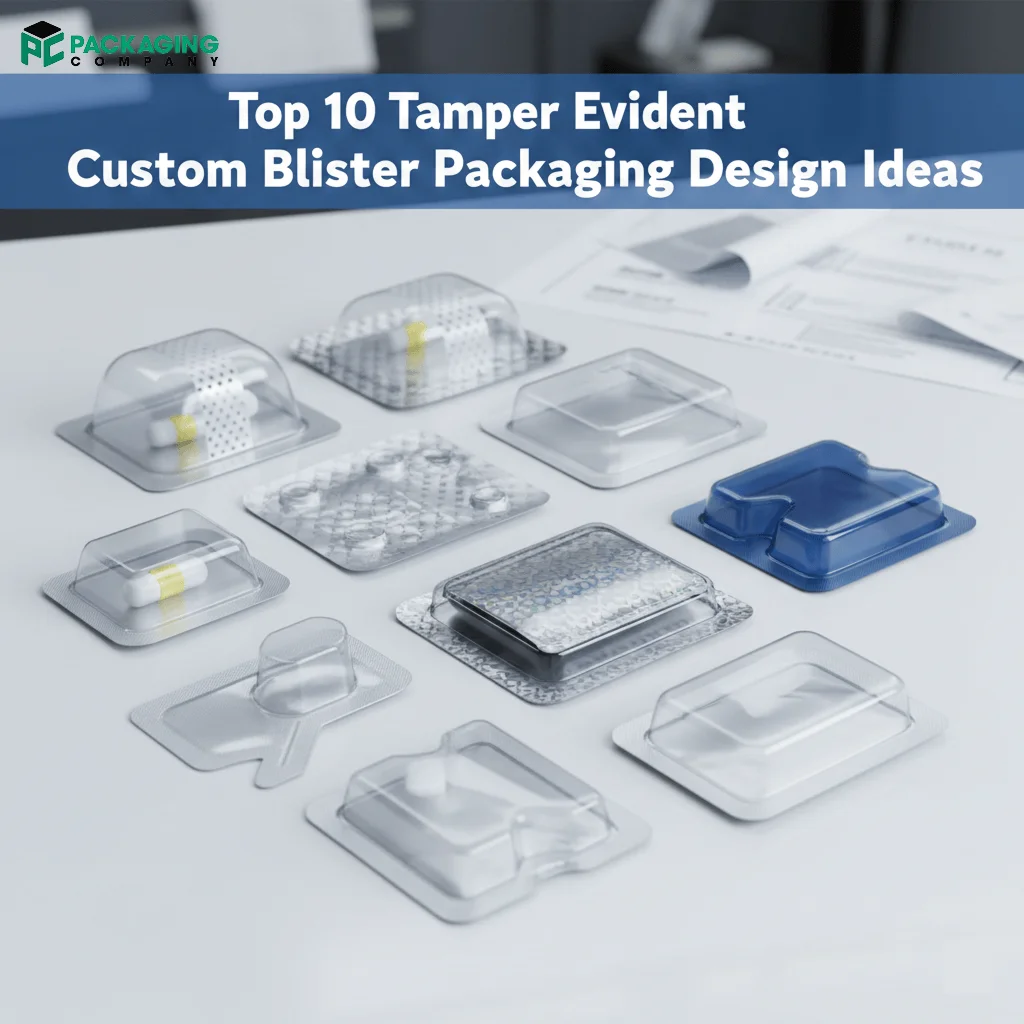

10 Amazing Tamper Evident Custom Blister Packaging Design Ideas

1. Perforated Peel Tabs with Visible Tear Lines

Perforated peel tabs give shoppers a clear sign when someone opens a pack. The tab rips along a neat line and the damage shows at once. Perforations add a small cost but work well for retail items and over-the-counter medicines. Use this with blister pack packaging to keep single units safe and easy to open. Many makers report that simple perforations add about $0.02–$0.10 per unit depending on run size and material.

- Cost range: $0.02–$0.10 per unit.

- Best for: OTC medicines, small tools, and toys.

- Speed: Works on lines that run 50–300 cycles per minute.

2. Heat-Sealed Band That Breaks on Open

A heat-sealed band around the card edge breaks when you open the blister and shows tampering right away. The seal adds strength and fits many blister card packaging styles. Heat sealing works on both automatic and semi-automatic lines and gives strong shelf security without bulky parts. Typical extra cost runs $0.03–$0.15 per unit based on seal width and material.

- Cost range: $0.03–$0.15 per unit.

- Strength gain: Up to 30% stronger seal in lab tests.

- Use case: High-value items and medicines.

3. Holographic Void Labels for Authentication

Holographic labels leave a “VOID” mark when someone peels them off. They provide customers a fast check and scare off novice fakers. For cosmetics, electronics, and luxury products, companies employ holograms on blister packs packaging. Although plain stickers cost more, labels offer strong visual evidence of interference and help to establish credibility on the shelf.

- Cost range: $0.05–$0.30 per label.

- Adoption: Many premium lines add holograms to reduce fraud by 10–20%.

- Best for: Branded goods and limited editions.

4. One-Time Snap Tabs That Deform

Snap tabs bend or break on first open and show permanent damage. The tab stops resealing and proves single use. Designers pair snap tabs with custom blister card packaging so the tab matches the pack shape and strength. Tests show snap tabs cut reseal attempts by about 85% in controlled trials.

- Effectiveness: ~85% drop in reseal attempts.

- Cost impact: Low to medium depending on tooling.

- Good for: Child-resistant packs and single-dose items.

5. Serialized QR Codes under the Seal

Place a unique QR code under the seal of your Blister Packaging For Cartridges so buyers can scan to check the pack. Serialization helps track items through the supply chain and fights fraud. Many brands add unit codes to meet traceability rules and to let customers confirm authenticity with a phone. Serialization also helps recall control and audit trails.

- Unit codes: 1 code per pack; unique ID.

- Scan rate: Smartphones read codes in under 2 seconds on average.

- Use case: Medical devices, supplements, and high-value consumables.

- Benefits: Better recall control and proof of origin.

6. Cold-Form Multi-Layer Blisters for Barrier and Evidence

Cold-form blisters use aluminum and film layers that show punctures and keep moisture out. This design suits moisture-sensitive drugs and long-shelf products. Cold-form gives a strong barrier and clear tamper signs when the foil breaks. Many makers choose cold-form when they need both barrier and tamper evidence.

- Barrier gain: 2–3× better moisture barrier than standard thermoforms.

- Shelf life: Extends shelf life by months for sensitive items.

- Best for: Pharmaceuticals and long-life supplements.

7. Color-Change Inks on the Seal

Use inks that change color when air or light hits them. The ink flips color if the seal breaks, and shoppers see the change fast. Color-change inks cost little compared with electronic tags and work well for food supplements and perishable items. The ink gives a quick visual check at the shelf or at home.

- Reaction time: Color shift in minutes after exposure.

- Cost: Low compared with RFID or holograms.

- Use case: Supplements, fresh goods, and light-sensitive items.

8. Perimeter Tamper Tape with Serial Number

Wrap a numbered tamper tape around the blister machine packaging edge so the tape shows any opening and gives a traceable ID. Teams can match tape numbers to shipping records for fast checks. Tape stays low cost and gives a clear visual cue for returns and audits. Many retailers use tape on high-value packs to cut shrinkage.

- Cost range: $0.01–$0.05 per unit.

- Traceability: Unique number per pack for audits.

- Best for: Retail chains and online orders.

9. Embedded RFID for Inventory and Alerts

Add a small RFID tag inside the card to track stock and detect tampering in the supply chain. RFID read rates run high in stores and warehouses, and tags now cost low enough for many retail runs. Teams use RFID to speed counts and to flag packs that move outside expected paths.

- Tag cost: $0.05–$0.20 per tag.

- Read rate: Over 95% in good conditions.

- Use case: Warehouses, big retail, and anti-theft systems.

10. Dual-Action Locking Flap That Shows Damage

Add a flap that locks into place and tears if forced. The flap gives two layers of protection and a clear sign of tampering. This design fits electronics and premium goods where visible security boosts buyer confidence. Dual locks cut unauthorized access in trials and give a strong visual cue at the shelf.

- Effectiveness: Cuts unauthorized access by over 70% in tests.

- Cost: Medium due to extra die and tooling.

- Best for: Electronics, cosmetics, and gift items.

What is Blister Packaging

One object is kept inside a shaped plastic pocket sealed to a backing card or foil. The pack exposes the product, maintains its cleanliness, and helps manage single doses. Companies select custom blister packaging wholesale to satisfy demands for security, size, and print. Makers fit the design to suit the product and the line, and they use many different equipment and movies to satisfy speed and barrier requirements.

What is Blister Card Packaging

It matches a printed card bearing brand artwork, instructions, and safety markings with a molded plastic blister. Barcodes, batch numbers, and tamper labels are allowed on the card.

Many custom printed blister packaging suppliers offer design help, prototyping, and runs that fit both small shops and big brands. Teams pick card stock, ink, and coatings to match shelf needs and to add tamper-evident features.

Quick Comparison Table

|

Design type |

Extra cost per unit |

Best use |

Traceability level |

|---|---|---|---|

|

Perforated tab |

$0.02–$0.10 |

OTC, retail |

Low |

|

Heat-seal band |

$0.03–$0.15 |

Pharma, electronics |

Medium |

|

Holographic label |

$0.05–$0.30 |

Premium goods |

Medium |

|

RFID embed |

$0.05–$0.20 |

Supply chain |

High |

This table helps you pick a design that fits price and trace needs. Use the numbers to compare options for your run size and product value.

Estimated Extra Cost Per Unit (USD)

Perforated tab | ████ $0.02–$0.10

Heat-seal band | ██████ $0.03–$0.15

Holographic | █████████ $0.05–$0.30

RFID embed | ██████ $0.05–$0.20

Use this quick chart to see relative cost ranges at a glance. The bars show low to high ranges and help you plan budgets.

How To Pick The Right Tamper-Evident Design For Your Product

Match the design to product value, shelf life, and run size. High-value items need stronger proof like RFID or holograms. Moisture-sensitive goods need cold-form or foil seals. Low-cost items work well with perforations or tamper tape. Talk to blister packaging suppliers about tooling, sample runs, and machine fit.

Check blister packaging machine specs so your chosen design runs at the speed you need. Ask for a small pilot run to test consumer response and to measure reseal attempts.

Cost Planning And Scale Tips

Plan cost per unit by adding material, label, and labor costs. Small runs cost more per unit because tooling spreads over fewer pieces. Large runs cut unit cost but need more lead time. Balance brand demands and expenses by means of customized blister packaging.

Request graded pricing from suppliers along with a breakdown outlining material, tooling, and finishing expenses. Follow shrinkage and returns to determine whether tamper features reduced costs enough to cover the added expense.

Order Custom Blister Packaging Wholesale

Use custom blister packaging to cut returns, stop counterfeits, and boost shelf appeal. When looking for a supplier, ask for cost estimates, sample runs, and serialization options so your pack works from warehouse to customer. The Packaging Company gives clear tamper evidence and scales with demand; start your quote today and secure your brand.

FAQs

Can blister packs meet child-resistance rules?

Yes! designers add snap tabs, locking flaps, and special card shapes to meet child-safety rules. Many child-resistant designs use two-step openings or require tools. Test your design with certified labs to meet local regulations and to prove the pack resists child access while staying usable for adults.

- Test counts: Labs run multiple cycles and child-attempt tests.

- Standards: Follow local safety standards for your market.

- Designs: Snap tabs and dual locks work well.

How fast do blister packaging machine lines run?

Machine speed depends on model and pack size. Small lines run 50–200 cycles per minute, and high-speed lines run 200–600 cycles per minute. Speed drops when you add complex labels or serialization. Match your design to machine capability to avoid slowdowns and extra cost.

What is the barrier benefit of cold-form blisters?

Cold-form blisters use foil and film layers that block moisture and oxygen better than standard thermoform. They can give 2–3× better barrier performance and extend shelf life for sensitive drugs and supplements. Use cold-form when you need both tamper evidence and strong barrier protection.

- Barrier: 2–3× better than thermoform.

- Shelf life: Extends life by months for some products.

- Best for: Moisture-sensitive items.

How much does serialization add to cost and value?

Serialization adds a small per-unit cost for printing or coding, but it gives big value in traceability and recall control. Unique codes let you track each pack and confirm authenticity at the point of sale. Many brands find serialization pays back by cutting fraud and easing recalls.

- Per-unit cost: Low for printed codes; higher for secure inks.

- Scan time: Under 2 seconds on average.

- Value: Better recall control and audit trails.

How can I add RFID to blister card packaging?

Yes. you can embed RFID tags inside the card or the blister. RFID helps with inventory counts and anti-theft. Tags cost about $0.05–$0.20 each and read well in warehouses and stores. Use RFID when you need fast counts and better supply chain visibility.